“FASTER WITH AND

EASIER MAINTENANCE-

ACME CRUSHERS

GET IT DONE!”

A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening. Gyratory crushers can be used for primary or secondary crushing.

Major components can be divided to ease transport restrictions; i.e., spider 3 pieces, top frame 2 pieces each for upper and lower, bottom frame 3 pieces.

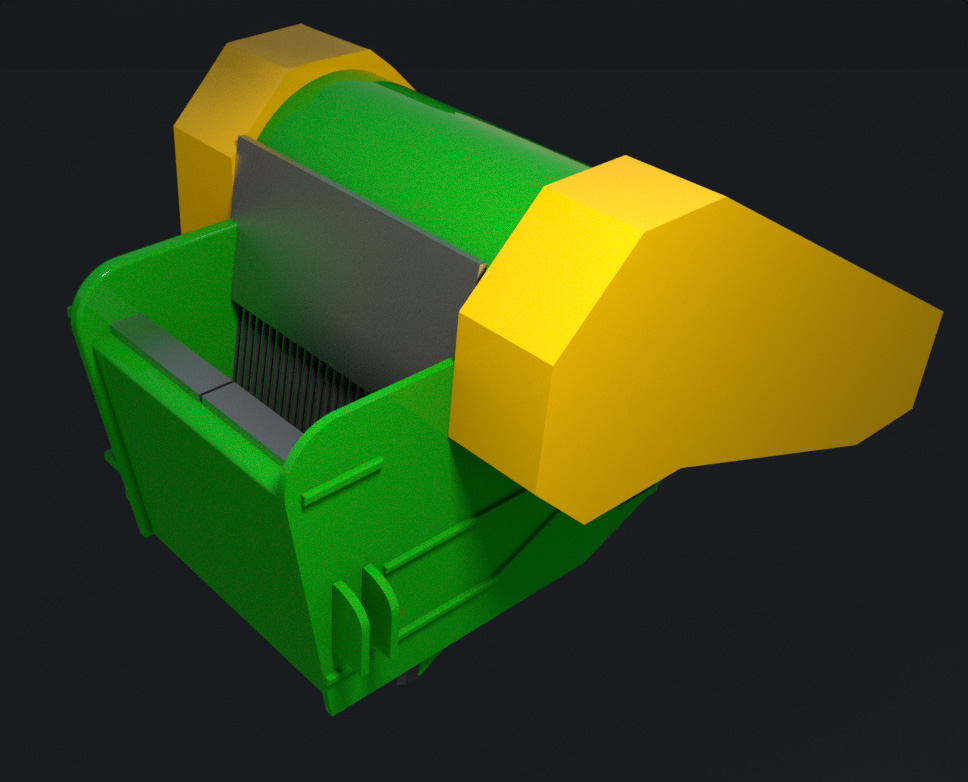

This is a type of crusher that is widely used in the primary and secondary crushing processes.

It is usually preferred for the crushing of large blocks of hard and abrasive materials. The moving jaw moves back and forward against the fixed jaw, and material fed from the top of the machine is compressed between the two, breaking it into smaller pieces.

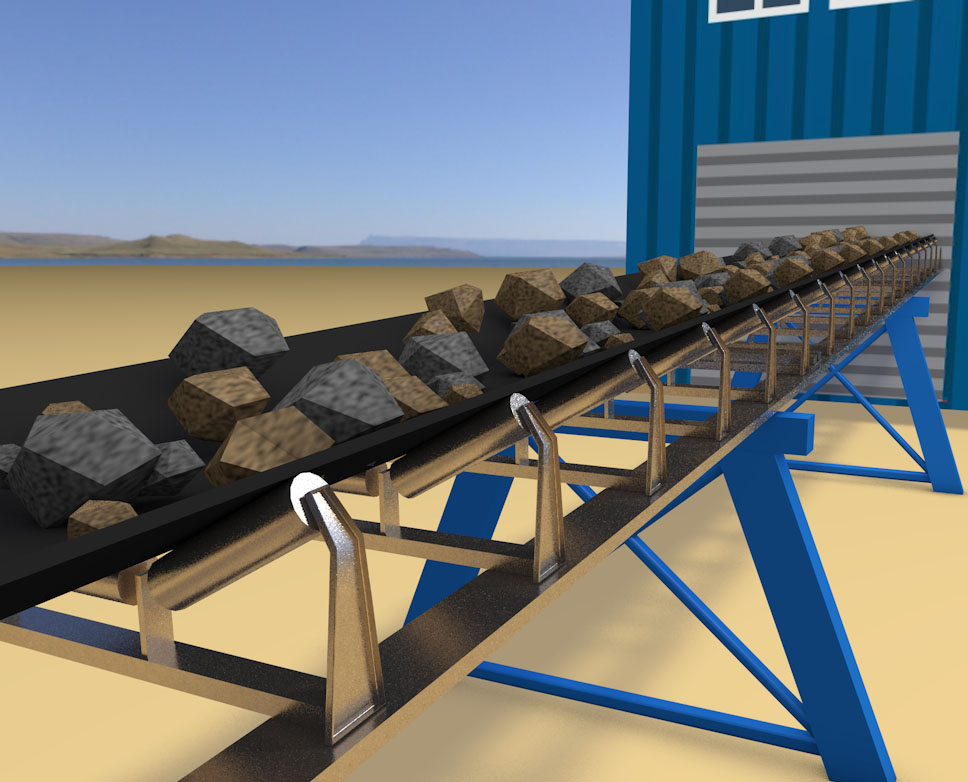

Cable Belt is a unique conveyor design that is well suited for long distance conveyor applications where vertical and horizontal curves are required. The design differs to that of conventional conveyor designs. The conveyor belt is supported by two endless wire rope cables, one on each side of the belt, in lieu of idlers. The belt has almost no tension induced as it simply “goes along for the ride”.

Truck haulage is the most common form of materials transport in open pit mines. Trucks can be used to haul ore and waste out of the mine or they can be used to haul to an in-pit crusher where ore and/or waste can be crushed and then conveyed out of the mine. The trend has been towards larger and larger open pit trucks to match larger shovels and excavators. Trucks have the advantage over rail and conveyor systems where the haulage distance is relatively short and flexibility is needed.

Primary gyratory crushers are the initial driving force for the entire mineral processing circuit. ACME GYRO-CRUSH XT primary gyratory crushers provide high throughput and less downtime to bring maximum efficiency to your operation.

Primary gyratory crushers are the initial driving force for the entire mineral processing circuit. ACME GYRO-CRUSH XT primary gyratory crushers provide high throughput and less downtime to bring maximum efficiency to your operation.

Value stands out from whatever perspective you look at the GyroCrush XT from. Productivity? We got it! Ease of maintenance? We got it. Reliability? We more than “got it”. We CRUSH IT!